Nanotechnology refers broadly to a field of applied science and technology whose unifying concept is the control of matter on the molecular level in range smaller than 1 micrometre, usually 1 to 100 nanometres.

Nanotechnology is becoming a critical driving force behind innovation in medicine and healthcare, with a wide range of advances including nanoscale therapeutics, biosensors, implantable devices, drug delivery systems, and imaging technologies. In medicine, it promises to revolutionize targeted drug delivery, gene therapy, diagnostics, and many areas of research, development and clinical application.

But Ayurveda, which is thousands of year old science, has a field called as “Rasashastra”, in which numerous pharmaceutical methods are developed by which metals and minerals are changed into quite fine, absorbable, therapeutically most effective and least or non-toxic form of medicines known as Bhasmas.

Use of metals and minerals in therapeutics has been found since Vedic period, which became an important part of Ayurvedic therapeutics due to their additional advantages like smaller doses, quick action etc. Animal’s derivative such as horns, shells, feathers, metallic, non-metallic and herbals are normally administered as Bhasma.

Prof. AK Tyagi of the Babha Atomic Research Centre (BARC), said that, bhasmas’ used in Ayurveda for treatment of various diseases for the past several centuries, is the oldest form of nanotechnology.

Bhasmas are very fine ayurvedic medicinal powders prepared by the process of calcination of metals, gems or minerals. Calcination, is the heating of solids to a high temperature for the purpose of removing volatile substances, and converting them into oxides. Calcination, therefore, is sometimes considered a process of purification.

Bhasma are manufactured with a series of preparation methods which includes detoxification of raw materials, crushing them with herbal juices, making small pieces, drying and heating. The end product of these long term preparation methods are residues of metals and minerals.

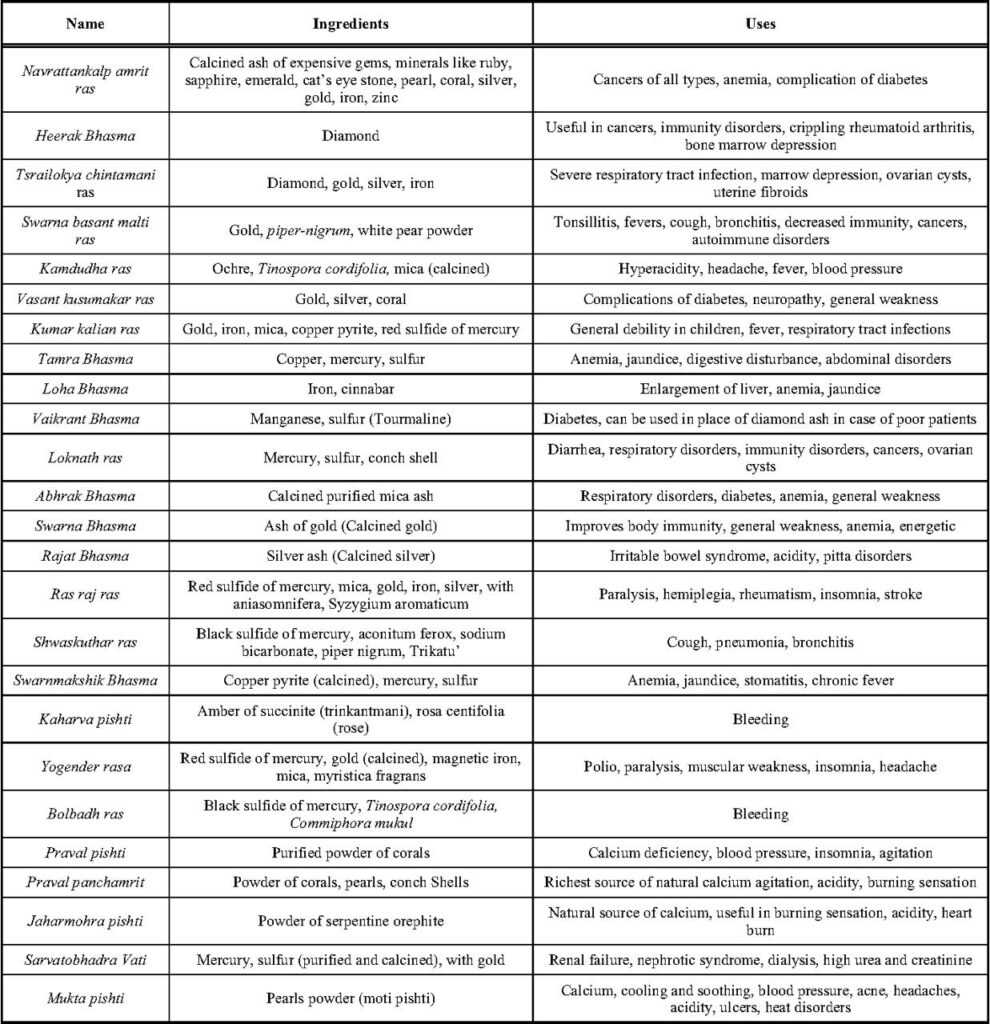

Bhasmas mostly contain various metals like Gold, Silver, Copper, Zinc having end products like Swarna bhasma, Rajat Bhasma, Tamra bhasma and Yashad Bhasma respectively. Bhasmas mostly prepared by use of Mardan (grinding) and Maran (Incineration) of metals and Ayurvedic drugs herbal juices with some important Ayurvedic drugs for the processes.

It is these bhasmas, which can be considered the earliest form on nanomedicine. Concept of reduction in particle size of metals is prevailing since Charaka Samhita (1500 BC). Bhasma, is a distinctive Ayurvedic mixture containing herbs, minerals and metals, which are usually 5–50 nm in dimensions.

The nature of mineral/metal based drugs is that they function best when changed from their original state to its oxide state. The process of making is very organized and complicated, called “Bhasmikarana” which converts the metal to a form with higher oxidation state. This eliminates the toxic nature of metal and imparts high medicinal value to it.

During Bhasmikarana, metals/minerals are treated to different processes of purification and incineration which aims to reduce the particle size. This process helps in converting them into biocompatible, biodigestible, absorbable and a suitable form for the human body. Bhasma nanoparticles are organometallic or organomineral compounds having improved stability, performance, absorption, assimilation, bioavailability, biocompatibility, effectiveness and targeted delivery of the element.

All Bhasma have some familiar features such as Rasayana (immunomodulation and anti-ageing property), Yogavahi (target drug delivery), Alpamatra (given in minimal doses), Rasibhava (readily absorbable, digestible and nontoxic), Shigravyapi (spreads quickly and fast acting) and Agnideepana (increases metabolism at cellular level and acts as a catalyst).

For e.g. gold in traditional Indian Ayurvedic medicine as Swarna Bhasma (gold ash) has been characterized as globular particles of gold (average size, 56-57 nm). The therapeutic value of Suvarna (gold) metal was known to ancient acharyas. It is widely described in Upanishads, Puranas and Smrities.

When we listen about the use of bhasmas, there is a widespread belief of its toxic effects in humans. There have been consumers who have suffered from toxicity of long term use of talc based powders. But in all the cases, the minerals used in these companies were definitely impure or un-purified. This is exactly like taking a untested and low quality allopathic medicine.

Bhasmas safety has been evident with practice since ancient times, scientifically proven through toxicity studies & clinical safety. Bhasma of Rajat, Loha, Tamra, Yashada, Naga and Vanga etc. have proven to be safe in various studies.

The alleviation of a disease depends upon the quality of Bhasma prepared through standard procedures. The standardization of Bhasma is utmost necessary to confirm its identity and to determine its quality, purity safety, effectiveness, and acceptability of the product.

Commonly practiced metallic preparations are i.e., loha bhasma, abhraka Bhasma, swarna bhasma, tamra bhasma etc. The Bhasma preparation steps are as follows:

- Shodhana (Purification): raw metals for the bhasma are obtained from ores, which generally contain unwanted impurities. The impurities are removed by the process of shodhana. The resultant product can be subjected to undergo the process of bhasmikarana .i.e., Marana.

- Bhasmikarana (Marana): is the process to eliminate the toxicity or undesired effect of the specific material. This process develops the biocompatible qualities in substance following the purification processes. The substance develops the desired physical and medical properties i.e., palatability, bioavailability, microscopic particle size etc.

- Maran (Powdering): is the process which transforms the metals into a suitable and desired biocompatible form for assimilation of phytochemicals in next phase.

- Chalana (Stirring): is the process of heating the powdered metal and stirring.

- Dhavana (Washing): the shodhana or marana phase co-agents are removed by the process of dhawana by water. These residuals can impact the quality of final products.

- Galana (Filtering): the material is sieved through a fine sized mesh sieves or cloth. The galena process helps to separate the residual material particles of larger size.

- Puta (Heating): the pure product of bhasmiakarna is heated on high temperature to incinerate in process of puta. These are the general steps used in preparation of a bhasma. The standard procedures and co-agents can be different for a specific substance to produce bhasma.

Bhasmas are said to neutralize and breakdown the harmful heavy metals and radicals in body; help in kidney, liver & gut issues; help in improving bone density; manage insomnia & depression etc. They are also used in respiratory disorders, arthritis, anaemia, fibroids, high blood pressure, hyperacidity, hormone optimization, cardiovascular health etc.

Best part is that, bhasmas are extremely potent in small doses, are virtually tasteless, are very fast acting due their nano size, have high bioavailability, and are quite stable as compared to other forms.

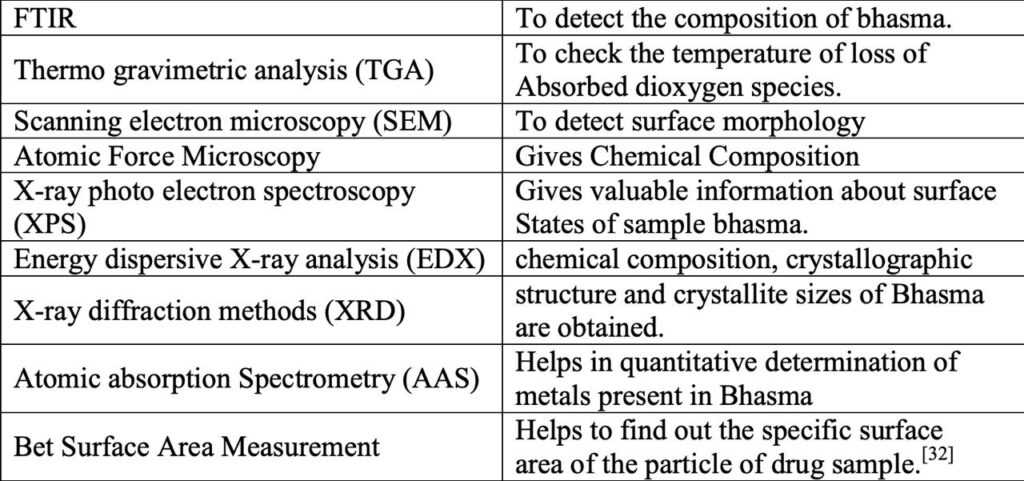

There are a range of scientific instruments used to assess the quality and various properties of bhasmas: